Lumidox® II LED Arrays

U.S. Patent No. 11,458,447

Analytical’s patented LED arrays provide wavelength and power specific illumination to samples for photoredox catalysis applications.

- Up to 15 different color wavelengths are available*

- 5 output STAGES (customizeable) with calibration data stored on board**

- Available in two Surface Mat styles

- Three options for Base configurations

(see the expandable section below: "Learn more about LED Arrays")

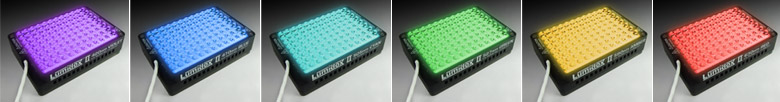

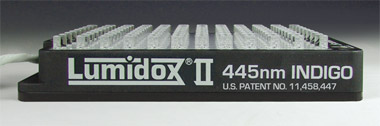

Lumidox II LED Arrays are available in up to 15 wavelengths*:

365nm UV, 375nm UV, 385nm UV, 395nm UV, 405nm UV, 420nm-Violet, 445nm-Indigo, 470nm-Blue, 505nm-Cyan, 527nm-Green, 590nm-Amber, 630nm-Red, 660nm-Deep Red, 730nm-IR Infrared and White. Note: LUM2CON controller is required to power LED arrays.

365nm UV, 375nm UV, 385nm UV, 395nm UV, 405nm UV, 420nm-Violet, 445nm-Indigo, 470nm-Blue, 505nm-Cyan, 527nm-Green, 590nm-Amber, 630nm-Red, 660nm-Deep Red, 730nm-IR Infrared and White. Note: LUM2CON controller is required to power LED arrays.

* Most LED arrays (excluding Discovery) are wavelength-specific - only one wavelength per device

** Calibration data is stored onboard (not on the controller), allowing the use of different illuminators with one controller. Controller can only operate 1 device at a time. STAGE settings are NOT user-adjustable and must be configured prior to shipping

** Calibration data is stored onboard (not on the controller), allowing the use of different illuminators with one controller. Controller can only operate 1 device at a time. STAGE settings are NOT user-adjustable and must be configured prior to shipping

Learn more about LED Arrays -

Surface Mat Styles

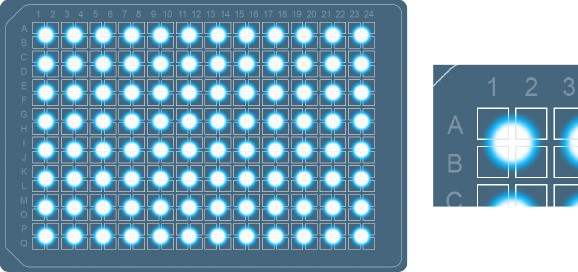

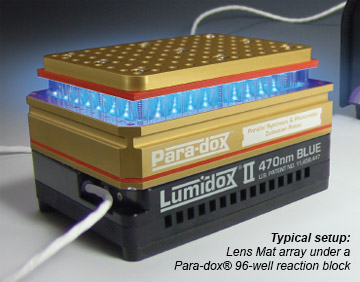

Array top surfaces come in two styles, Lens Mat and Diffuse Mat.

Lens Mat Surface

- Ultra-clear, molded to fit into the holes of a Para-dox® Reaction Block

- Captures nearly all light emitted by the array’s LEDs and directs it into the vials in the reaction block

- Chemically inert silicone

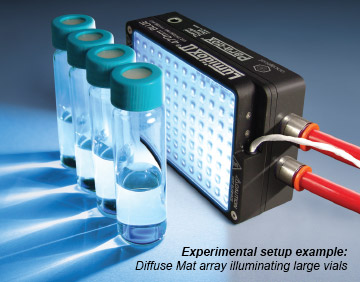

Diffuse Mat Surface

- Flat surface, making for easy pairing with SLAS footprint apparatus

- Can be used for niche applications such as illuminating cell culture flasks, reservoir plates, large scale containers, etc.

- Chemically inert silicone

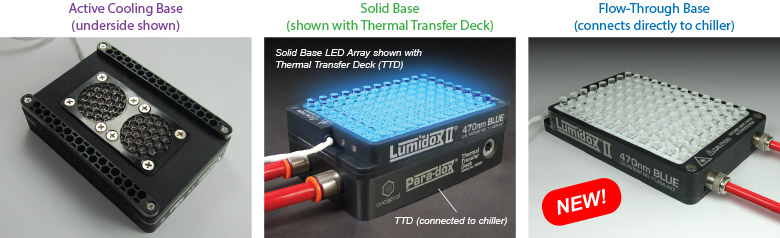

About Array Cooling and Base Options

Lumidox® II LED Arrays can generate a considerable amount of heat at any output stage and therefore need to be cooled. Both Lens Mat and Diffuse Mat style arrays are available with an Active Cooling base, Solid base or Flow-Through base. Each has it’s own specific way of cooling the LEDs in the array and can affect different application situations.

Active Cooling Base:

- Self-cooling, no external cooling source required

- Fully conforms to SLAS/ANSI standard dimensions

- Ideal for lower output applications like cell culture and PCR work (may require special adapter)

- Not compatible with tumble stirrers or devices that generate powerful magnetic fields

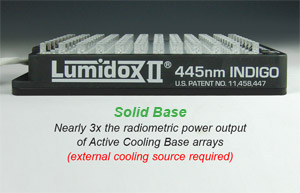

Solid Base:

- External cooling source is required (see Thermal Transfer Deck)

- A Thermal Transfer Deck (TTD) is recommended and can be attached to the base when used in conjunction with a recirculating chiller. The TTD can be removed if using a different cooling source, such as a cooling bay

- Fully conforms to SLAS/ANSI standards and can be used with cooling baths, plates, or other cooling chamber (if NOT being used with our Thermal Transfer Deck and recirculating liquid chiller)

- Ideal for applications requiring high output - up to nearly 3x more radiometric power output than Active Base arrays

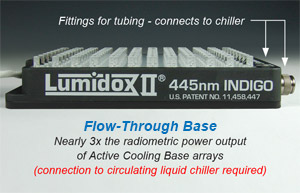

NEW! Flow-Through Base:

Note: Flow-through base LED arrays can only be used with an independent, dedicated recirculating chiller circuit. They cannot be daisy chained with any other hardware.

- Provides the most optimal cooling efficiency for LED arrays

- Direct connection to recirculating liquid chiller (required). Cooled liquid flows through the array base itself (no need for Thermal Transfer Deck)

- Ideal for applications requiring high output - up to nearly 3x more radiometric power output than Active Base arrays

- Light Weight – improved usability with orbital shakers due to lower overall mass

- Shorter overall height than active base array – offers improved compatibility with tumble stirrers (less distance between stirrer and sample)

Note: Flow-through base LED arrays can only be used with an independent, dedicated recirculating chiller circuit. They cannot be daisy chained with any other hardware.

For added protection, each device has a built-in thermal cutoff switch that, in case of overheating, will automatically shut down the unit. The trip temperature for Solid Base and Flow-thru Base Arrays is 95°C, and will reset when cooled to 65°C. Active Cooling Base Arrays will shut down if their temperature exceeds 75°C. They will reset once they have cooled to 45°C.

Note: Active Cooling Base arrays are not compatible with strong magnetic fields such as those found in most tumble stirrers due to interference with the cooling fans.

|

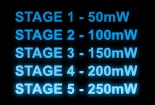

Lumidox® II STAGES By default, all Lumidox II devices are factory calibrated with 5 discrete linearly stepped output STAGES... |

Lumidox® II STAGE Selection

By default, all Lumidox II devices are factory calibrated with 5 discrete linearly stepped output STAGES (Example 1, below). STAGE 1 output is the least radiometric power while STAGE 5 output is the most. For LED arrays with Active Cooling Stage bases, STAGE 5 thermal dissipation requirements are configured to an appropriate level for each device's built-in thermal satisfaction abilities. STAGE 5 defaults for Passive (solid) Base Arrays are tuned to be thermally satisfied with an average powered chiller in thermal contact with the array base. STAGES are calibrated to nearest whole number of radiant flux, and displayed in milliwatts (mW).

Analytical Sales & Services offers custom tuned stages to meet specific and unique requirements. A user, for example, may have a more sophisticated cooling mechanism and require an array tuned for maximum light output. In this scenario, Analytical would tune the upper STAGES to higher levels than typically thermally controllable by standard users (Example 2). In another example, a user may have a need for a tighter resolution of STAGES (Example 3).

|

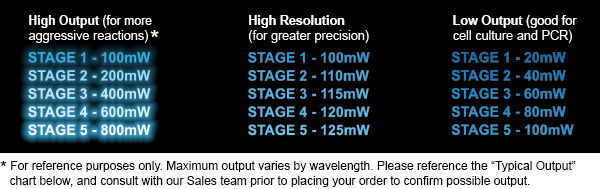

Typical Spectral Characterization

|

|

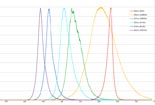

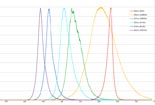

Typical Spectral Characterization

|

UV Wavelengths

|

Typical Spectral Characterization

|

Visible Wavelengths

|

Typical Spectral Characterization

|

Broad Spectrum Wavelengths

|

Typical Spectral Characterization

|

Infrared Wavelengths

Transparent orange acrylic is excellent for blocking UV and blue (365 to 470nm) light. We recommend 1/8" thick material.

Yes. Stagnant VOC vapors will permeate the LEDs, potentially leading to discoloration and/or damage, which may be reversible. If sufficient ventilation for VOCs cannot be provided, please periodically run your array on stage 5 for 2-3 hours with a fan blowing on the LEDs to completely burn away all the VOCs and revert the array back to its original state. See Product Note: Lumidox® II LED Arrays and VOCs

Yes, please contact engineering@analytical-sales.com for assistance. We will be able to walk you through the process. Please be sure to navigate to the "Additional Information" tab on our Lumidox controller webpage ahead of time, and download the firmware update files. Within that folder will be an executable file named GUI5R7529.exe. This is the GUI that we will utilize to make the changes to the array. Please contact your IT department if the file is blocked. You will also require the USB Cable that was provided with your controller.

We do provide some Python scripts for convenience. These downloadable files can be found under the “Additional Information” tab of the LUM2CON product page. Please note that the use of scripts for the Lumidox controller is experimental and not a supported commercial feature.

Our Lumidox units are easy to integrate with automation systems, as they were designed with this intention in mind.

The serial commands themselves plus some sample Python files can be downloaded from the "Additional Information" tab on our Lumidox controller page. Note that these features are currently experimental, and not yet officially supported.

The available commands in Lumidox Controller II – Serial Commands guide should cover all of the tasks needed to integrate and fire the units with your automation platform. Analytical also has "extension" cord sets available to extend the distance the array can be from the controller.

Collapse

LED Arrays for TCR

96-Position, Single Wavelength LED Arrays

U.S. Patent No. 11,458,447 Use with Para-dox® Standard 96-Position Aluminum Reaction Blocks for photoredox catalysis applications.

96-Position Discovery LED Arrays

U.S. Patent No. 11,458,447 Lumidox® II Discovery LED Arrays for screening offer researchers an economical and time-saving way to evaluate all of the wavelengths that the...

24-Position, 18mm Spacing LED Arrays

U.S. Patent No. 11,458,447 Use with Para-dox® 24-Position Aluminum Reaction Blocks with 18mm Spacing for photoredox catalysis applications.

24-Position, 255nm-UVC Arrays for Quartz Vials

Our 255nm UVC wavelength LED Array opens the door to exciting new applications—from high-energy photochemistry to polymer resin curing and surface disinfection—making...

24-Position, 9mm Spacing LED Arrays

U.S. Patent No. 11,458,447 Use with Para-dox® 24-Position Aluminum Reaction Blocks with 9mm Spacing for photoredox catalysis applications, or HTe-Chem Assemblies for...

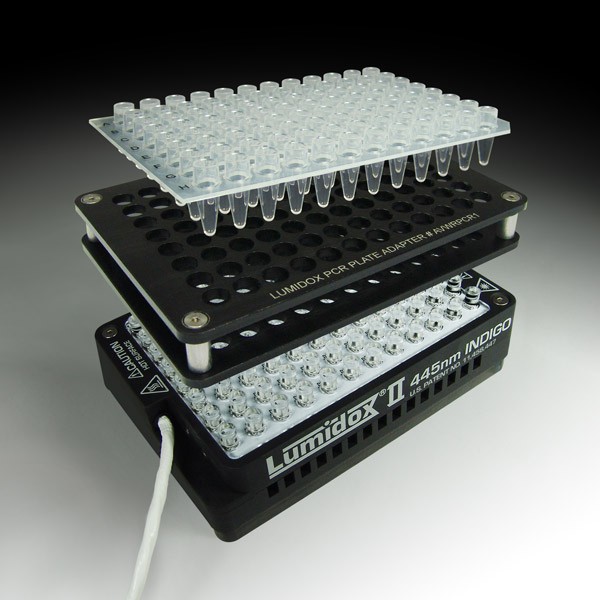

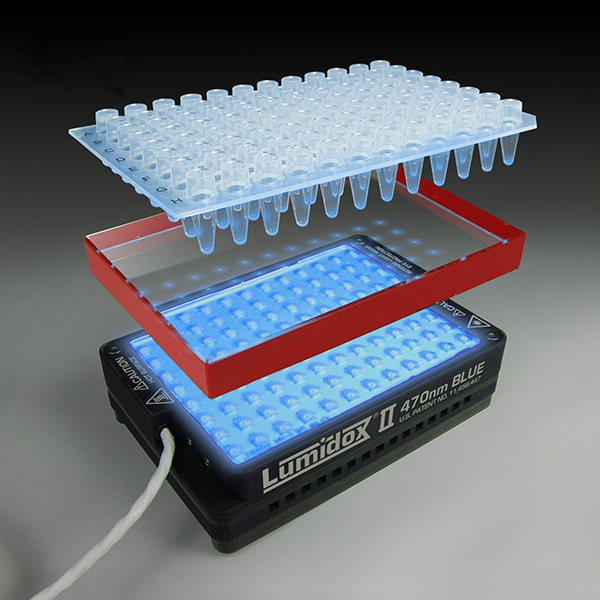

PCR Plate Adapters

If your workflow involves the use PCR plates, then Lumidox® II Lens Mat Arrays are perfectly suited for your research. Lumidox II Arrays generate highly precise,...

Cell Culture Plate Alignment Spacers

Glass Block for Light Reduction (PCR, Cell Culture)

Use to reduce the amount of light intensity delivered to your samples by increasing the distance between the samples and the light source (LED array). Place the Glass Block...