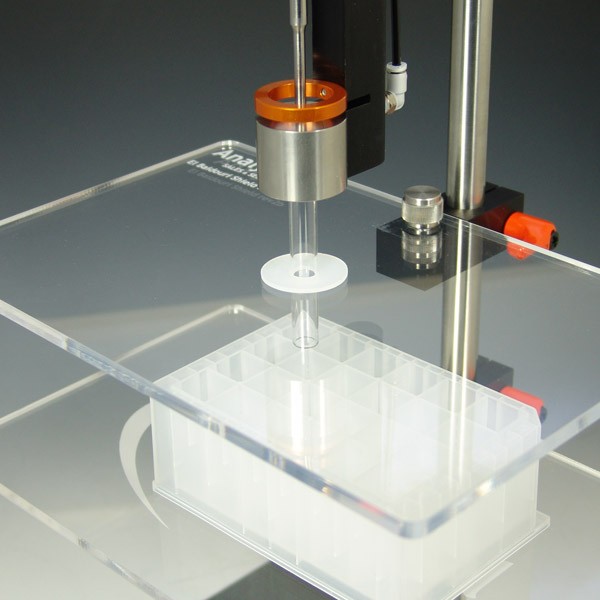

DBS-Dried Blood Spot Card Punch

In the realm of dried blood spot (DBS) testing, the DBS Punch is unique! It eliminates hand fatigue and blistering from the use of handheld manual card punches. It's a pneumatic foot pedal-controlled “power punch" that

increases speed and efficiency when loading dried blood spot samples into collection plates or tubes. The units require 90-110 PSI in order to properly operate; no electricity is required.

DBS Card Punch used in case study. See: Design and implementation of multiplexed amplicon sequencing panels to serve genomic

epidemiology of infectious disease: A malaria case study (section 2.4)

DBS Complete Systems

Punch Pods Only

Replacement Cutters

Select a cutter size that matches your pod head. Replacement cutters are not interchangeable with different size pods and can not be used to change punch head cuttings...

Replacement Pipettes