Flow Electrolysis

Replication is an impediment in the path of scientific progress, especially for experiments conducted using electrolysis. This challenge primarily comes from an abundance of non-standard setups requiring bespoke components, converting valuable experimental time into time spent on manufacturing and calibration. Necessary equipment causes further issues of yield since flask-based batch reactors lack a fresh supply of reactant, causing reaction efficiencies that decay over time.

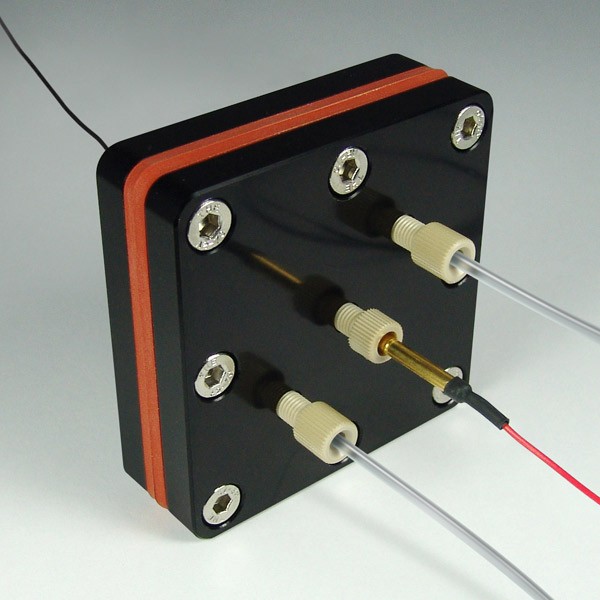

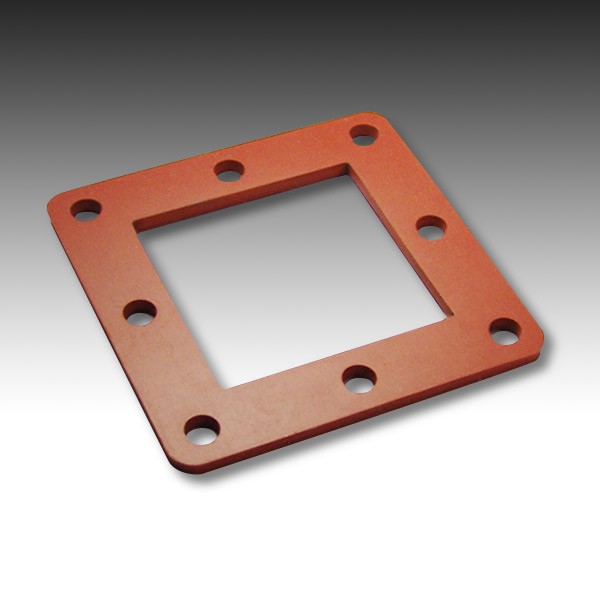

Analytical is pleased to offer a solution in the form of a standardized flow electrolysis setup. This new and upcoming technology allows for rapid and efficient production of complex chemical compounds via flow electrolysis. With an interelectrode gap smaller than a millimeter, and the introduction of flow geometries that promote turbulent mixing, our Flow Electrolysis Cell allow for heightened selectivity and yield when compared to flask based reactors. Additionally, the Flow Electrolysis Cell requires minimal new equipment to use. With fittings for 1/8” OD HPLC tubing, fluid flow and protruding electrodes can be connected to power supplies via standard connectors.

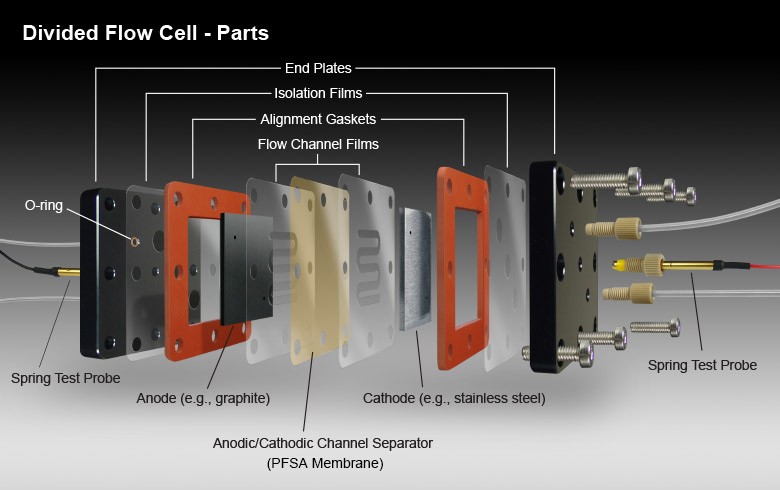

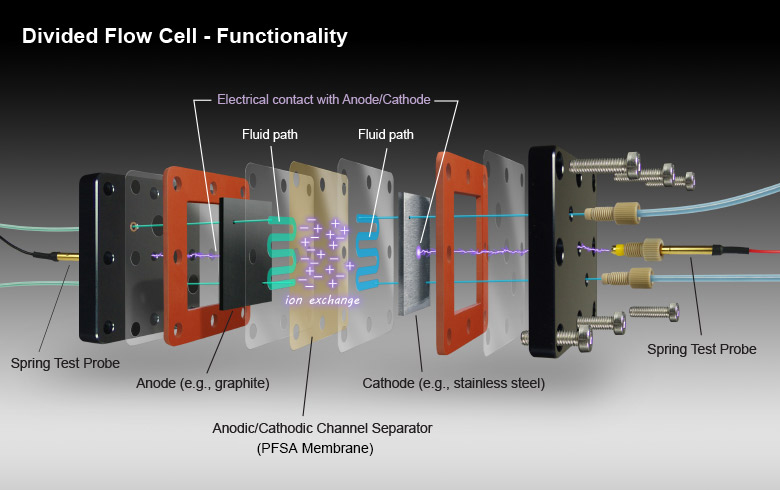

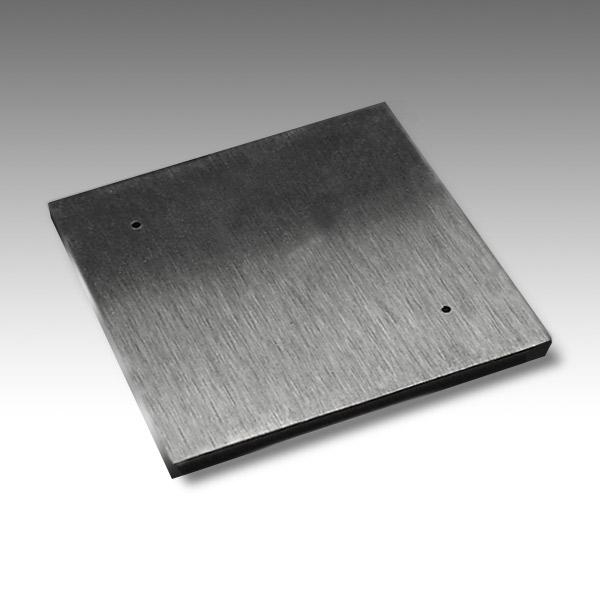

Analytical offers both a divided undivided cell. This capability opens up new experimental possibilities and allows swift development of novel and useful compounds, particularly in the field of organic electrosynthesis. In an undivided cell, both electrodes are washed with the same electrolyte and only one fluid circuit is used; the opposite side of the cell is sealed with HPLC plugs and an electrode without through-holes. This allows for low-resistance reactions which will output combined products. In a divided cell the electrodes and their flow channels are separated by a PFSA Membrane, allowing for reactions to be performed that produce separate output streams. This can be advantageous if the two electrolyte solutions are incompatible or if the products of their reaction are troublesome to separate. Individual components are also offered, making it easy to convert a divided cell to an undivided cell and vice versa. Higher efficiency and the ability to customize is critical to your experimental needs which is why Analytical offers a variety of different electrodes and flow channels.

The flow electrolysis setup features a convenient 80mm footprint, and thanks in part to mixing geometry flow channels designed to promote chaotic mixing and turbulence, an improved increase in the average yield by over 6% can be achieved. Analytical has the products required to meet your scientific needs.

Article: Green-Chemistry-SI.pdf

Article: Chemistry-Methods-2021-1-36-41.pdf

Article: SI-Chemistry-Methods-2021-1-36-41.pdf

Flow Electrolysis Cell Assemblies

Electrode Plates for Flow Electrolysis Cells (5 x 5cm)

Flow Electrolysis Consumable Accessories